Search This Supplers Products:PCB Magazine LoaderPCB Magazine UN-LoaderPCB SeparatorPCBA Cleaning machineBGA Rework StationPCB Inspection Conveyor

Electric Stencil Cleaning Machine -SME-800

- group name

- Stencil cleaning Machine

- Min Order

- 1 set

- brand name

- SAMTRONIK

- model

- SME-800

- Nearest port for product export

- San Deigo, Bangkok, Singapore, California

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union, Cash

- Export mode

- Export through agents

- update time

- Wed, 04 Mar 2026 22:12:59 GMT

Paramtents

Stencil size 750mm(L) ×750mm(W) × 40mm(H) as max

Capacity of tank 60L x2 pcs. ( liquid tank and water tank)

Clean time 3~5 minutes

Clean heater power 9KW

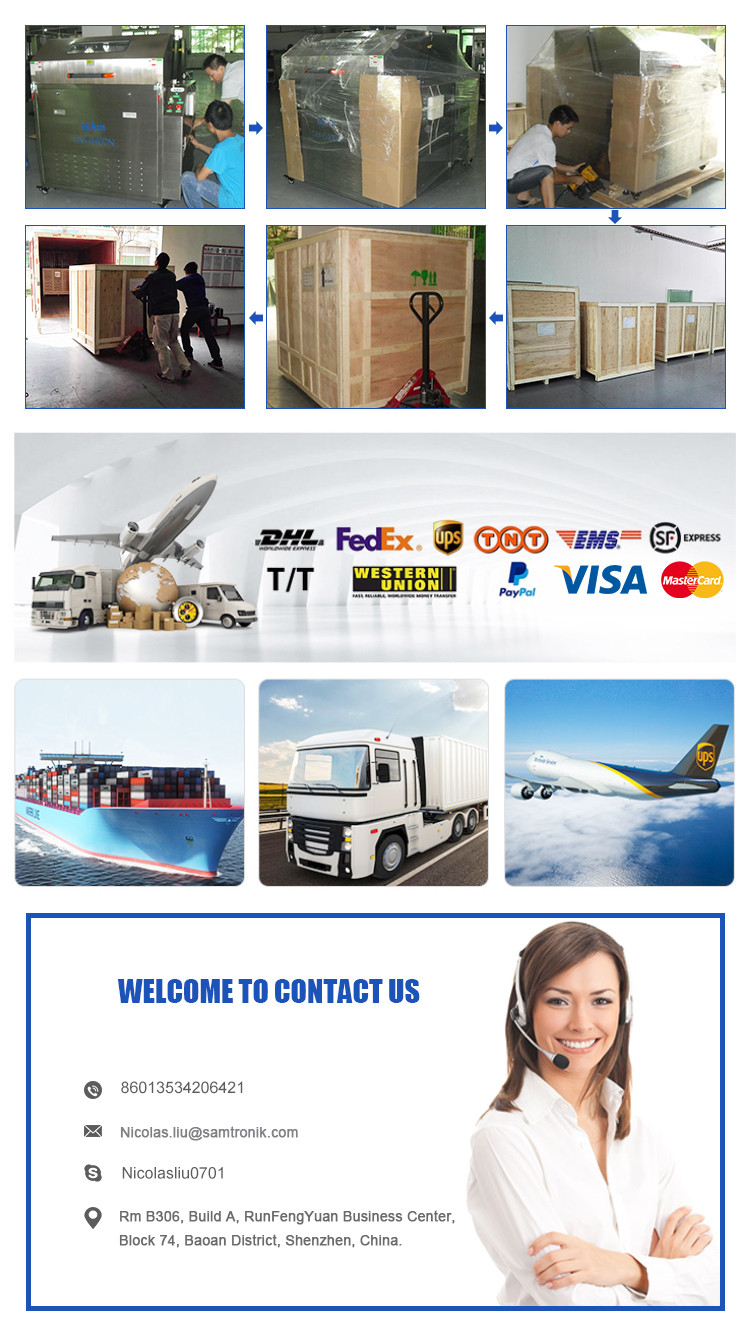

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

Electric Stencil Cleaning

Machine -SME-800

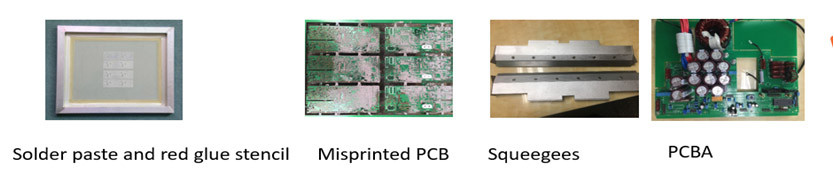

Clean

solder paste stencil;

Clean

red glue stencil, Resin mask, Copper mask;

Clean

misprinted PCB;

Clean Big size PCBA.

Clean

squeegee

Features:

1, aquesous

cleaning liquid, clean +rinse+dry process.

2, Not

only setncil ,but also cooper stencil, mis-printed PCB, squeegees.

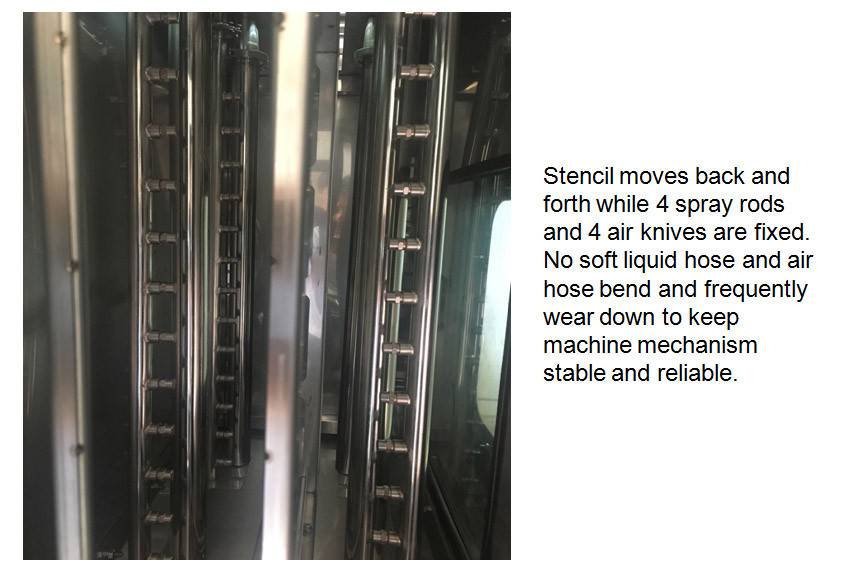

3, The

best mechanism design--stencil move back and forth while spray rods and air

knives on the two sides of stencil fixed.-- make the machine stable and very

few frictions.

4, no

soft liquid hose or hot air hose broken frequently because of high liquid and

air pressure and hose frictions.

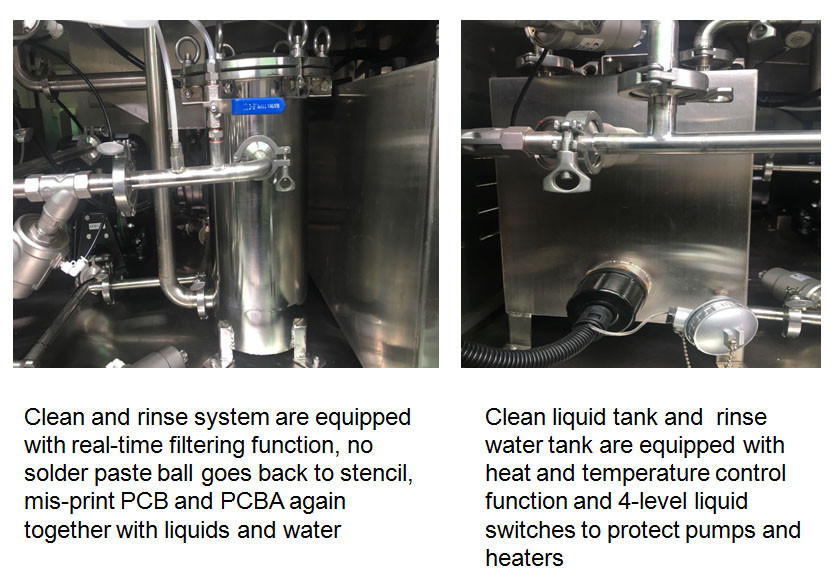

5, Real

time filtrer system, make liquid and water can be recirculated used,save liquid

and water, no solder balls comes back to stencil surface again after clean and

rinse off. Especially for precise stencil' clean.

6, 4

spray rods with spray nozzles on it ,conver all the surface of stencil.

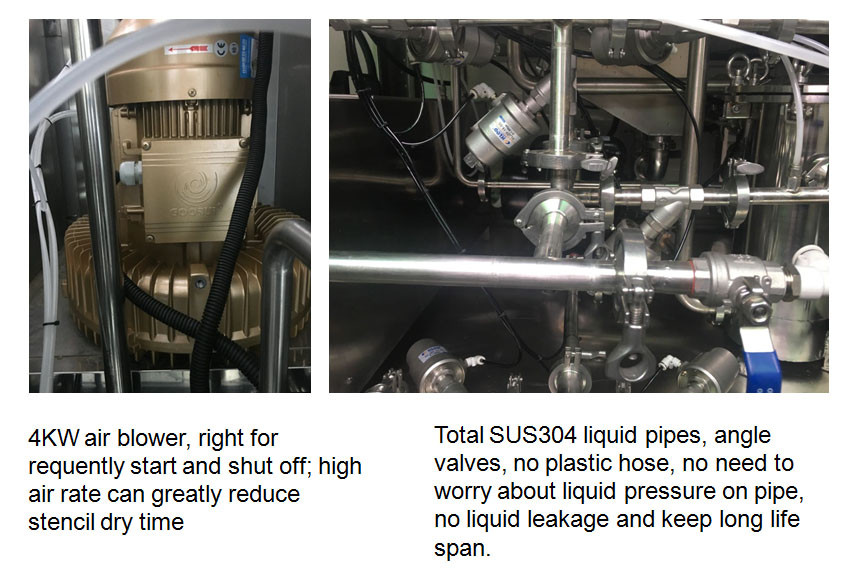

7, 4

air knives with high volume and high pressure air blower, make it dry the

stencil quickly.

8, SUS304

stainless steel structure, all machine parts which connected liquid, water or

hot air are SUS304 material. solid and stable.

9, One

key easy operation, all cleaning ,rinse and dry process are completed in one

cycle.

10,Visible

window on cleaning chamber, all process are visible.

11,Compressed-

air blow out remain liquid in pipes after cleaning process, save up to 50%

liquid.

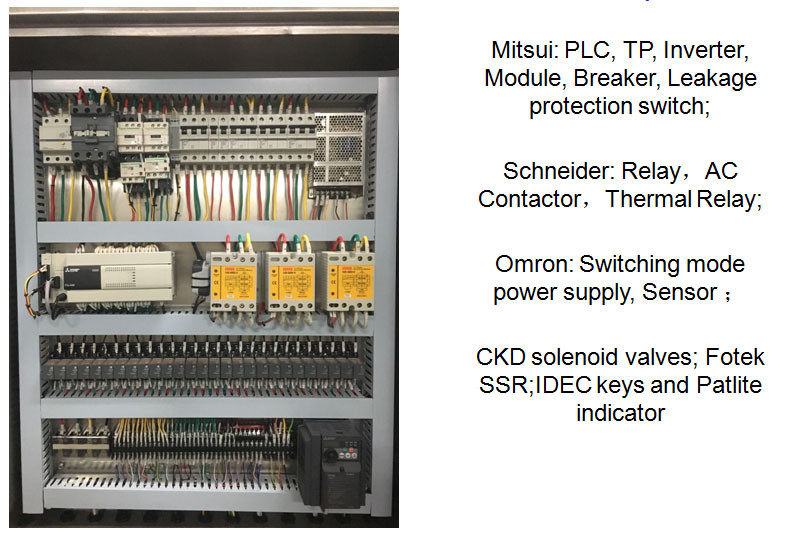

12,PLC

control, TP English interface, 20 sets of programmes can be set and edited.

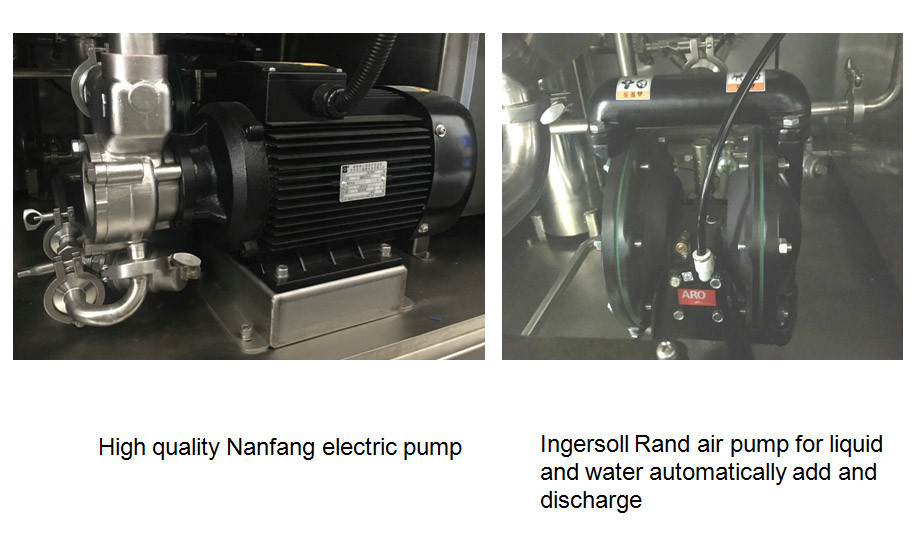

13,Equipped

with air pump liquid/water add and drained automatically accroding to

requirement.

14,world

wide famous brand, high quality electric parts, penumatic parts, reliable and

stable.

15,High

cleaning efficiency;

16,Low

liquid consumption

Description:

The

most stable cleaning mechanism

Electric

pump and air pump

Filters

and liquid tanks

Air blower and pipe system

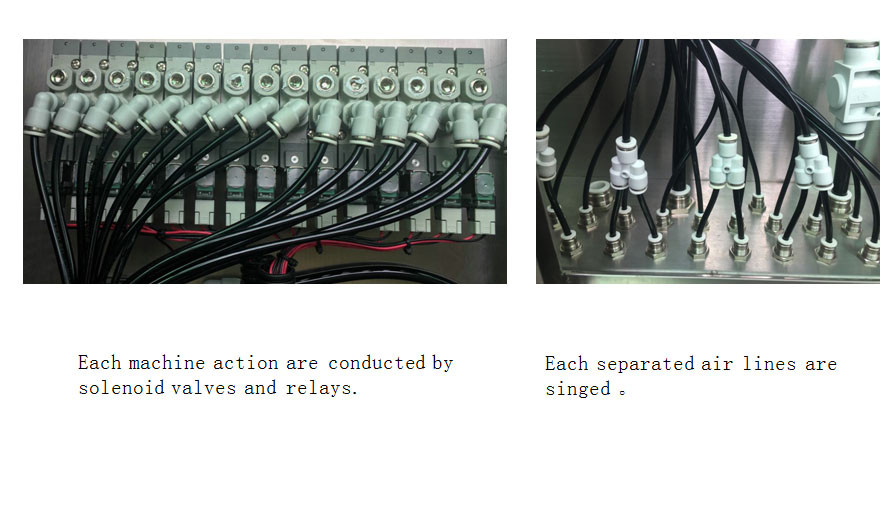

air control system

Famous

electric parts and reliable control system

Specifications:

|

No. |

Item |

Specification |

|

1 |

Stencil size |

750mm(L) ×750mm(W)

× 40mm(H) as max |

|

2 |

Capacity of tank |

60L x2 pcs. ( liquid tank and water tank) |

|

3 |

Clean time |

3~5 minutes |

|

4 |

Rinse time |

1~2 minutes |

|

5 |

dry time |

3~6 minutes |

|

6 |

Clean liquid |

aqueous cleaning

liquid for cleaning |

|

7 |

rinse liquid |

DI water or DM water |

|

8 |

clean/rinse method |

high pressure liquid/water spray clean and rinse |

|

9 |

dry method |

hot air blow dry |

|

10 |

Liquid or water

heat temp |

room

temperature to 60oC |

|

11 |

Dry air heat temp |

room temperature

to 90oC |

|

12 |

Clean heater power

|

9KW |

|

13 |

rinse heater power |

9KW |

|

14 |

Dry heater |

6KW |

|

15 |

Filter grade |

1μm for cleaning,

1 μm for DI water |

|

16 |

Electric pump |

4HP stainless

steel l pump |

|

17 |

Hot air blower |

5.5 HP |

|

18 |

Exhaust air vent |

Φ120mm |

|

19 |

Power supply |

380VAC, 3 Phase,

50HZ , 33KW(13kw when macine is working) |

|

20 |

Air supply |

0.5~0.7Mpa |

|

21 |

Weight |

720KG |

|

22 |

Dimension |

1300mm(L)

×1400mm(W) × 1950mm(H) |

Company

Profile

About Samtronik

Samtronik is a professional one-stop SMT Equipment service

provider , With more than 10 years Electronic Manufacturing Service factory

Equipment selling experience .

Samtronik mainly supply pcb handling equipment ,PCB Separator

,screw locking machine , smt cleaning machine , smd counter , smd taping

machine ,smt parts etc .

Why Choose Us

1.We

promise customer response within 24 hours;

2. Well-trained and experienced staffs to answer

all your enquires in fluent English;

3.Best products and price to offer;

4.Shortest time to delivery the products ;

5.All machine will be strictly testing before

shipment;

6.OEM & ODM services offered;

7.Best Guarantee :With 1 years warranty !

Product

Packaging &Contacting Us